Dammsugarvagn typ DB "Gleisreinigungswagen", för DC

Dammsugarvagn typ DB "Gleisreinigungswagen", för DC

-

Secure payment in our shop!

Secure payment in our shop!

Dammsugarvagn typ DB "Gleisreinigungswagen", för DC system, fungerar både analogt och digitalt, längd över buffertar 185 mm.

SSF-09 kontrollmekanik med automatiskt start/stop funktion och faulhabermotor.

Vikt cirka 140 gram, bredd 39 mm, NEM 362 koppelficka.

Strömförbrukning 200 mA.

Vacuum cleaner wagon AC System for analog and digital operation.

With SSF-09 control mechanic (automatic start/stop function) and faulhaber motor.

With the track vacuum cleaner, you can remove ...

Dust and dirt particles from the circulating air and the site construction

... and thus achieve:

Functional reliability of the model railway vehicles

safe power take-off from rail and center conductor

trouble-free driving

The mobile and fully functional Lux track vacuum cleaner car for all H0 track and control systems was specially created to remove loose dust and dirt particles from the entire track area.

Experience has shown that it is precisely these dirt deposits from the circulating air and the construction of the terrain that impair the safe functioning of the precision mechanical components (gears, coupling rods, axle bearings, power contacts, etc.). Even the finest dirt on the rail head can lead to significant operational disruptions.

The innovative and reliable cleaning technology of the Lux track vacuum cleaner car is built into a rail vehicle, so that particularly inaccessible areas of your model railway system such as tunnels, shadow stations and track systems spanned by overhead contact lines etc. The maintenance-free operating times of the rail vehicles can thus be increased significantly.

The track vacuum cleaner car is supplied with power via the traction voltage and can be pulled or pushed by standard traction vehicles. He has no drive to move.

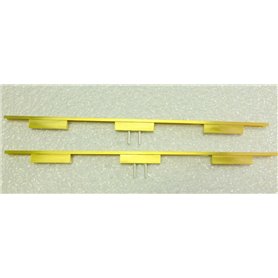

The vehicle is equipped with close coupling kinematics and NEM coupling receptacle. Power is supplied via the 4th point wheel contact set or the ski grinder on the car's bogie. The cleaning technology is driven by a durable and maintenance-free bell armature motor (Faulhaber1).

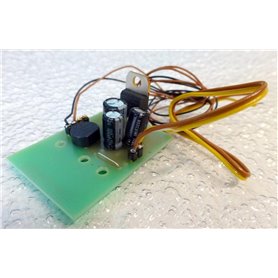

The innovative control electronics SSF-09 (automatic start / stop function) work based on movement. When the car is moved on the powered track (pulled or pushed by a locomotive), the cleaning technology switches on automatically. If the moving, activated cleaning trolley comes to a stop (e.g. signal stop), the cleaning technology switches off automatically. The cleaning trolley can be used on analogue and digitally controlled systems.

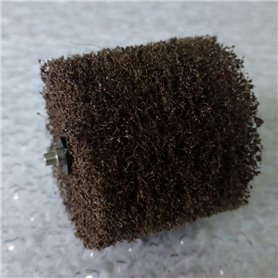

The suction brush is fixed to the chassis floor and can be replaced. This ensures that the brush works optimally at threshold height. It loosens the fine particles from the sleeper grid and the rail. The dirt particles are fed to a collecting container via the suction nozzle. The sucked in air escapes through a microfilter in the

Cover of the dust container.

An Fe1 H0 scrap collector (item no. 8828) for collecting ferrous deposits (nails, screws, chips) in the entire track area is available as an accessory kit for all H0 track vacuum cleaner cars. Attention! Can only be used to a limited extent with reed contacts.

Technical specifications:

The vehicle was designed taking into account the standards of European model railways and is protected by patent. The H0 track vacuum cleaner car can be used with standard half-wave and pulse-width controls.

Power supply 0-24 volts AC / DC

Current consumption approx. 200 mA

max.motor voltage 5 volts DC

Coupling pocket according to NEM 362 standards

Weight approx. 140 grams

Height above rails upper edge 54 mm

Length over the buffers 185 mm

Width 39 mm

Vehicles for 2L = direct current (DC) can also be equipped with RP25 wheel sets on request.

Equipment:

Wear parts:

Replacement suction brush (Item No. 8840).

Replacement required after approx. 1 - 5 years (depending on how dirty the system is).

Retrofit parts:

H0 scrap collector Fe1 (Item No. 8828).

For picking up ferrous objects (nails, screws, shavings, etc.) from the entire track area.

- Scale

- 1:87

- Country

- DB

- Current

- DC

- Option

- Analog

Digital