Rälsrengörningsvagn för mittenledare DB för AC

Rälsrengörningsvagn för mittenledare DB för AC

-

Secure payment in our shop!

Secure payment in our shop!

Rälsrengörningsvagn för mittenledare DB för AC.

Rälsrengörningsvagn för mittenledare DB för AC system (Märklin), fungerar både analogt och digitalt, längd över buffertar 185 mm.

MLR-1 center conductor cleaner

for all H0 track and control systems (Märklin systems) analog and digital.

With SSF-09 control electronics (automatic start / stop function), Faulhaber¹ motor and battery station.

Available as a complete vehicle (only for cleaning the center conductor).

With the MLR-1 center conductor cleaner you can remove from your point contacts ...

stuck oil and dirt residues

Deposits from traction tire wear

Oxide layers

... and thus achieve:

significantly higher operating hours of the vehicles

safe power take-off from the center conductor

trouble-free driving

The MLR-1 center conductor cleaner was created by us for problem-oriented center conductor cleaning. It removes stuck oil and dirt residues as well as oxide layers from your center conductor. Even the finest dirt on the center conductor can lead to significant operational disruptions.

By installing the innovative and reliable cleaning technology in a rail vehicle, even particularly inaccessible areas of your model system such as tunnels, shadow stations and track systems spanned by contact wires can be cleaned without any problems. The maintenance-free operating times of your rail vehicles are significantly increased and a safe current consumption from the center conductor is achieved.

The fully functional and mobile central ladder cleaning trolley is supplied with power via the drive voltage and can be pulled or pushed by standard traction vehicles. He has no drive to move.

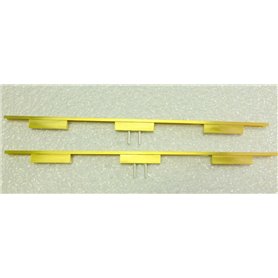

The vehicle is equipped with close coupling kinematics and NEM coupling receptacle. The power is supplied via the 4-point wheel contact set or the ski grinder on the car's bogie. The cleaning technology, the oscillating polishing body fixed in a bogie, is driven by a long-lasting and maintenance-free Faulhaber motor¹.

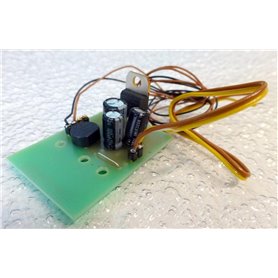

The innovative control electronics SSF-09 (automatic start / stop function) work based on movement. When the car is moved on the powered track (pulled or pushed by a locomotive), the cleaning technology switches on automatically. If the moving, activated cleaning trolley comes to a stop (e.g. signal stop), the cleaning technology switches off automatically. The cleaning trolley can be used on analogue and digitally controlled systems.

The battery station carried in the grinding carriage and charged via the track voltage buffers the cleaning technology motor in the event of a power failure on the rail / central conductor (e.g. due to dirt). This means that the MLR-1 center conductor cleaner maintains its cleaning effect even on short, currentless track sections.

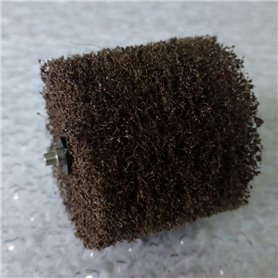

The centerpiece of the center ladder cleaning trolley is the oscillating sanding pad fixed in a bogie and covered with a cleaning strip.

The polishing technique, which is regulated in the center of the track and height-regulated in the case of curved tracks and especially when approaching points, works continuously on the center conductor. In this way, layers of oxide and dirt are removed in a highly efficient manner at the point of contact on Märklin1-M, K and C tracks as well as Trix Express tracks.

The encapsulated drive is optimally protected against contamination. The drive block is held in the car chassis by a support plate.

The different cleaning strips (Art.No. 9049 and 9050) guarantee an optimal cleaning effect at the point contact with the lowest possible static friction. The MLR-1 center conductor cleaner is equipped with cleaning strips (art.no.9049) as standard. The cleaning strips, saturated with dirt, must be replaced.

For information:

The individual grinding units (item no. 9030, 9032, 9033, 9034 and 9036) e.g. from the rail and overhead line grinding car can also be used in the MLR-1 center ladder cleaning car.

The MLR-1 center conductor cleaner is also only available as an interchangeable insert (see item no. 9029 and 9031) (see picture). It can be used in all H0 rail and overhead line grinding cars (AC ~ and Trix Express) and the H0 machine car (AC ~ item no. 9138) from Lux-Modellbau (see sketch, picture).

Technical specifications:

The vehicle was designed taking into account the standards of European model railways and is protected by patent. The integrated control electronics enable driving operation even with half-wave and pulse width controls.

Important! The control board carried in the vehicle protects the motor (max. 5 volts DC) from overvoltage and ensures that the sanding pad oscillates evenly.

Power supply 0-24 volts AC / DC

Current consumption approx. 110 mA

max.motor voltage 5 volts DC

Coupling pocket according to NEM 362 standards

Weight approx. 220 grams

Height above rails upper edge 54 mm

Length over the buffers 185 mm

Width 39 mm

Vehicles for 2L = direct current can be equipped with RP25 wheel sets on request.

Equipment:

Wear parts:

Replacement polishing material 1500 grit (Item No. 9049) standard.

Replacement is required when material is saturated with dirt or worn out.

Retrofit parts:

Replacement polishing material 800 grit (Item No. 9050).

Replacement is required when material is saturated with dirt or worn out.

H0 exchange - grinding mills (Art.No. 9030, 9032, 9033, 9034, 9036)

- Scale

- 1:87

- Country

- DB

- Current

- AC

- Option

- Analog

Digital